5/1 12 ... ok, the curly maple island is ready to go ... were going to move it in one piece to the site tomorrow, weather permitting. it was an interesting project, more complicated than it looks, and were looking forward to seeing it later this week with its granite top and sink installed in its new home. we finished it at the clients request with a wash coat of shellac and two wipe on coats of waterlox. very smooth feeling and easy to apply. fast drying too ... good job trevor ...

end view with the open shelves for large pots

other end

stool side ... still cant figure out this new blogger interface ... i may have to actually watch the video ..

..............................................................................................

........................................................ 4/12/2012 above ...........

island update 4/11 ..... ok, were coming along now ... after working out the construction details with the full size corner mockup in the two photos at the bottom of this post, we started actual construction by building the kick space directly on top of our full size cardboard layout drawing. on this drawing seen below, (a bad image, poorly photoshopped to compensate for low contrast and glare) we laid out our cabinet and corner post lines, the sink, and inverted between the orange lines, our vertical section which shows panel and face frame details .. click the photos to enlarge them ....

from that drawing and the original mockup, we turned our round column bases that the octagon columns sit on. we then drilled the rounds for timberlock lag screws which we used to attach the round bases to the tablesawn octagons. the orange arrows on those indicate the sawn faces which came out ever so slightly smaller than the planed faces ... it seems impossible to get them all perfectly the same size but we wanted the face that our face frames attached to to be all the same size. follow that? good for you. we notched the octagons for the face frames and routed L shaped recesses in the round bases for the little bead moldings that allowed us to transition the beveled tops of the turnings to the panels. got

that? really good ... i think you can see that detail in the mockup too.

i forgot to mention we also had to cut a freehand corner out of each round where it intersected the toe space on the bandsaw before attaching the whole deal to the kick with more timberlocks ... got

that?... im trying not to bore you with

all the details; but there were certainly a lot of things to think about on this project before we could even begin ...

now were on to the more straightforward part of the construction where we build the boxes and add the face frames and panels ...

one more shot of the base with its curly maple kick faces and all the columns in place.

and we had a moment where we stopped to appreciate mother natures veneer work with the naked lady doing a handstand ... fun!

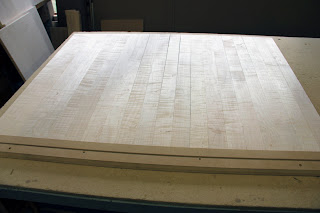

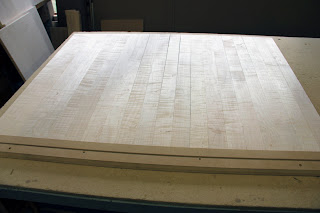

part of the project was that the owner would supply the wood, but after struggling mightily to make silk purses from not so great material, the owner graciously allowed us to get a bunch of matched curly maple lumber from our friends at irion, and you just cant believe how much happier we all are ... piece after consistent piece .... beautiful panel after beautiful panel, matched drawer face with matched drawer face ... its a true pleasure to work with their stuff ....

tomorrow we will finish the frame joinery and assemble it all for a test fit before gluing all the panels up .... more as we move it along ... were liking it ...

3/27/12

we have a new kitchen island project getting underchoice in the shop ... all natural curly maple with a stone top. open shelves,drawers, a recess for seating, pretty straightforward except for the octagonal columns on the corners .... finished my full size mockup today and once that is approved, well have at it ... click the photos to enlarge them ...

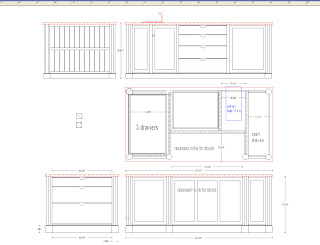

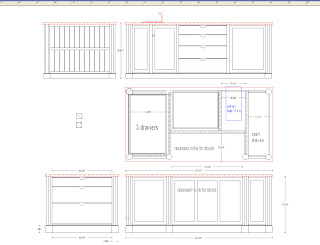

here are the cad drawings that we made from the owners graph paper layouts ... the plan view shows some of the complications where the octagonal columns meat the panels and cabinetry and open shelves but conceptually at least, i think we have it worked out .... were currently working from a full size 4 x 8 cardboard plan view which is a great tool for making cut lists and box sizes. we find the full size things can minimize errors and they dont take too long to create ...

since i sent these photos to the client, i thought i might add these examples of other islands we have built in case you are thinking about designing one yourself. the island above is in my home ... cherry counters with tile around the stove; the seating on the end is where we live, lunch and dinner, good for up to 5 people seated ...

and we built this one in 2007 i think ... it even made it into house beautiful ... actually, it was one of my very first blog posts in october of 2007

another view of it ... the rest of the kitchen and the reclaimed chestnut stools are ours too ...

and heres a nice walnut island for the same client who got the walnut paneled room in 2009...

another wash painted island, very similar in detailing to my own kitchen ... we did some tin punching on that project ...

and then theres the big island ... almost a continent by some reports ... quartered white oak

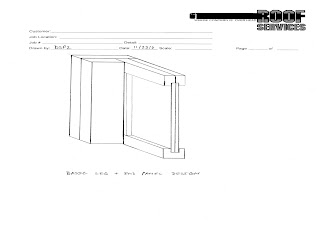

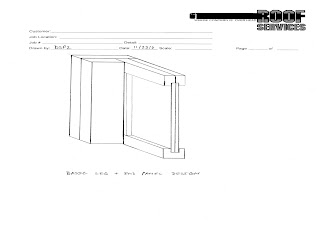

and here we arrive at the mockups for our new project ... the octagons seemed simple until i actually had to add the kick spaces and the turned round pedestals ...

the base will be the first piece and it will have a 3/4" top that the cabinetry will be attached to from above ... like a really big puzzle ... more photos as we progress ....

on site but the house isnt quite finished

All in , all done .... miracle recovery .... descriptive post below

We finished a couple of interesting repairs last week and I was sending photos to clients so I thought I would post them here too ... The bureau above is one of the last pieces of furniture we have to restore that was damaged in the fire I have occasionally written about. I thought it was a goner as it took several days in the sun to even get it open, and when we finally did, it really didnt look too promising ... Looks can be deceiving though and by the time Jim stripped the smoked shellac and sanded the interior and resealed it, I was starting to be just a little more optimistic. Click the photos to enlarge them ...

Here, Jim has stripped off the toasted shellac and sanded the interior, which he is now coating with a seal coat of shellac and wax to get rid of the smoke odor.

There were then some repair necessary to the face that that you can see in the first photo above ...

I chipped off what was left of the round corners and replaced them with new veneers. The masking tape was a good trick. It allowed me to bend the veneers cold without the pieces breaking or separating, kind of like a paper backed veneer would be, only thicker...

I taped them in place with the repair mans friend, 3M 2040 masking tape, a stretchy but strong and sticky clamp..

The stripped and sanded drawers ... Whats up with that top one? ..

We applied a thin coat of aniline dye, recoating some elements a couple of times to balance the color, and then shellaced with a wash coat of diluted fresh amber shellac. Well build slowly in thin coats from here until we reach the desired shine, which will not be too terribly shiny ... The hardware has been cleaned and reantiqued and is ready to go back on when the finish is complete ... I think it will look like a million bucks when its done ...

Another fire victim in the before stage ....

In the almost finished stage. The brass was polished and then reantiqued and the shellac was built slowly as mentioned above ... We finished the top with a coat of black patinating wax which was perfect for the job .... The Revere bowl was totally black and looked almost hopeless before Jim got to work on it ...

This is another repair that came through recently from Hildene, Robert Todd Lincolns home, in Manchester, Vermont. We had a huge windstorm a couple of weeks ago, which blew open the French doors at the house and knocked the table across the room

Before ...

After

I had a wonderful conversation with Kari a few weeks ago in which we both agreed that the space between the front & back legs of a bench does not need to be open (in line with the legs). That conversation confirmed an idea which has been brewing in my head for a few weeks: using panels in addition to stretchers between my front and rear legs. I think this will add both mass and stability to the bench.

After we talked I worked on some sketches of how to construct the legs.

|

The legs will be a 2x6 & 2x4. The double panels between

the stretchers will be 3/4" OSB on the outside &

3/4" MDF on the inside. |

Today while waiting for a meeting to start, I sketched some more. Im pleased with the choice the design is coming together.

|

This shows a cross section of the bench construction.

Sorry the leg cross sections are backwards, thats

the order I drew them. |

I need to do a little more research and then finalize it.

How is your bench leg assembly constructed?

its fall. the light is changing. you start to notice stuff. like chicken feathers. you gotta love those barred rock feathers ... this one has been stuck in my van dashboard for a few weeks now ...

and then theres the foliage... click the photos to enlarge them ...

makes the old back yard sparkle .. and vegetables !

and tomatilla skeletons

and the asparagus bed on almost frosty morning

and the last of the zinnias ... days are dwindling down ... a few more golf days, a few more tennis days, on to winter paddle tennis ... and more big claro walnut tables

all for now

Read More..

let us now talk about interior design and furniture making. they are related .... i have alchoices thought them to be separate disciplines, but in looking through my on site photos folder recently, i realized that making a piece of furniture, particularly a piece for a particular client, for a particular spot, with their design input, is more than furniture making. if you get it right, not only have you manifested their vision, but you have created for them a special place, a place where they too can see their vision. powerful stuff, when you think about it .... so, that said, i will be adding a new category to my blog, interior design, where occasionally i will post a few photos of successful collaborations that i feel meet the criteria above. like the sideboard above, some are from my own home, where the realization began; others from my local clients homes.click the photos to enlarge them ...

let us now talk about interior design and furniture making. they are related .... i have alchoices thought them to be separate disciplines, but in looking through my on site photos folder recently, i realized that making a piece of furniture, particularly a piece for a particular client, for a particular spot, with their design input, is more than furniture making. if you get it right, not only have you manifested their vision, but you have created for them a special place, a place where they too can see their vision. powerful stuff, when you think about it .... so, that said, i will be adding a new category to my blog, interior design, where occasionally i will post a few photos of successful collaborations that i feel meet the criteria above. like the sideboard above, some are from my own home, where the realization began; others from my local clients homes.click the photos to enlarge them ... this is one of my favorite before and after rooms ... the challenge was to take a little used guest room/fly tying spot and turn it into a husband and wife home office/fly tying spot ... lots of conversations, lots of drawings, lots of changes ... before above ...

this is one of my favorite before and after rooms ... the challenge was to take a little used guest room/fly tying spot and turn it into a husband and wife home office/fly tying spot ... lots of conversations, lots of drawings, lots of changes ... before above ...

we did, in the end, receive a couple of design awards for this one ...

we did, in the end, receive a couple of design awards for this one ...

........................................................ 4/12/2012 above ...........

........................................................ 4/12/2012 above ........... island update 4/11 ..... ok, were coming along now ... after working out the construction details with the full size corner mockup in the two photos at the bottom of this post, we started actual construction by building the kick space directly on top of our full size cardboard layout drawing. on this drawing seen below, (a bad image, poorly photoshopped to compensate for low contrast and glare) we laid out our cabinet and corner post lines, the sink, and inverted between the orange lines, our vertical section which shows panel and face frame details .. click the photos to enlarge them ....

island update 4/11 ..... ok, were coming along now ... after working out the construction details with the full size corner mockup in the two photos at the bottom of this post, we started actual construction by building the kick space directly on top of our full size cardboard layout drawing. on this drawing seen below, (a bad image, poorly photoshopped to compensate for low contrast and glare) we laid out our cabinet and corner post lines, the sink, and inverted between the orange lines, our vertical section which shows panel and face frame details .. click the photos to enlarge them ....

from that drawing and the original mockup, we turned our round column bases that the octagon columns sit on. we then drilled the rounds for timberlock lag screws which we used to attach the round bases to the tablesawn octagons. the orange arrows on those indicate the sawn faces which came out ever so slightly smaller than the planed faces ... it seems impossible to get them all perfectly the same size but we wanted the face that our face frames attached to to be all the same size. follow that? good for you. we notched the octagons for the face frames and routed L shaped recesses in the round bases for the little bead moldings that allowed us to transition the beveled tops of the turnings to the panels. got

from that drawing and the original mockup, we turned our round column bases that the octagon columns sit on. we then drilled the rounds for timberlock lag screws which we used to attach the round bases to the tablesawn octagons. the orange arrows on those indicate the sawn faces which came out ever so slightly smaller than the planed faces ... it seems impossible to get them all perfectly the same size but we wanted the face that our face frames attached to to be all the same size. follow that? good for you. we notched the octagons for the face frames and routed L shaped recesses in the round bases for the little bead moldings that allowed us to transition the beveled tops of the turnings to the panels. got  i forgot to mention we also had to cut a freehand corner out of each round where it intersected the toe space on the bandsaw before attaching the whole deal to the kick with more timberlocks ... got

i forgot to mention we also had to cut a freehand corner out of each round where it intersected the toe space on the bandsaw before attaching the whole deal to the kick with more timberlocks ... got  now were on to the more straightforward part of the construction where we build the boxes and add the face frames and panels ...

now were on to the more straightforward part of the construction where we build the boxes and add the face frames and panels ... one more shot of the base with its curly maple kick faces and all the columns in place.

one more shot of the base with its curly maple kick faces and all the columns in place. and we had a moment where we stopped to appreciate mother natures veneer work with the naked lady doing a handstand ... fun!

and we had a moment where we stopped to appreciate mother natures veneer work with the naked lady doing a handstand ... fun! part of the project was that the owner would supply the wood, but after struggling mightily to make silk purses from not so great material, the owner graciously allowed us to get a bunch of matched curly maple lumber from our friends at irion, and you just cant believe how much happier we all are ... piece after consistent piece .... beautiful panel after beautiful panel, matched drawer face with matched drawer face ... its a true pleasure to work with their stuff ....

part of the project was that the owner would supply the wood, but after struggling mightily to make silk purses from not so great material, the owner graciously allowed us to get a bunch of matched curly maple lumber from our friends at irion, and you just cant believe how much happier we all are ... piece after consistent piece .... beautiful panel after beautiful panel, matched drawer face with matched drawer face ... its a true pleasure to work with their stuff .... tomorrow we will finish the frame joinery and assemble it all for a test fit before gluing all the panels up .... more as we move it along ... were liking it ...

tomorrow we will finish the frame joinery and assemble it all for a test fit before gluing all the panels up .... more as we move it along ... were liking it ... we have a new kitchen island project getting underchoice in the shop ... all natural curly maple with a stone top. open shelves,drawers, a recess for seating, pretty straightforward except for the octagonal columns on the corners .... finished my full size mockup today and once that is approved, well have at it ... click the photos to enlarge them ...

we have a new kitchen island project getting underchoice in the shop ... all natural curly maple with a stone top. open shelves,drawers, a recess for seating, pretty straightforward except for the octagonal columns on the corners .... finished my full size mockup today and once that is approved, well have at it ... click the photos to enlarge them ... here are the cad drawings that we made from the owners graph paper layouts ... the plan view shows some of the complications where the octagonal columns meat the panels and cabinetry and open shelves but conceptually at least, i think we have it worked out .... were currently working from a full size 4 x 8 cardboard plan view which is a great tool for making cut lists and box sizes. we find the full size things can minimize errors and they dont take too long to create ...

here are the cad drawings that we made from the owners graph paper layouts ... the plan view shows some of the complications where the octagonal columns meat the panels and cabinetry and open shelves but conceptually at least, i think we have it worked out .... were currently working from a full size 4 x 8 cardboard plan view which is a great tool for making cut lists and box sizes. we find the full size things can minimize errors and they dont take too long to create ... since i sent these photos to the client, i thought i might add these examples of other islands we have built in case you are thinking about designing one yourself. the island above is in my home ... cherry counters with tile around the stove; the seating on the end is where we live, lunch and dinner, good for up to 5 people seated ...

since i sent these photos to the client, i thought i might add these examples of other islands we have built in case you are thinking about designing one yourself. the island above is in my home ... cherry counters with tile around the stove; the seating on the end is where we live, lunch and dinner, good for up to 5 people seated ... and we built this one in 2007 i think ... it even made it into house beautiful ... actually, it was one of my very first blog posts in october of 2007

and we built this one in 2007 i think ... it even made it into house beautiful ... actually, it was one of my very first blog posts in october of 2007 another view of it ... the rest of the kitchen and the reclaimed chestnut stools are ours too ...

another view of it ... the rest of the kitchen and the reclaimed chestnut stools are ours too ... and heres a nice walnut island for the same client who got the walnut paneled room in 2009...

and heres a nice walnut island for the same client who got the walnut paneled room in 2009... another wash painted island, very similar in detailing to my own kitchen ... we did some tin punching on that project ...

another wash painted island, very similar in detailing to my own kitchen ... we did some tin punching on that project ...

and then theres the big island ... almost a continent by some reports ... quartered white oak

and then theres the big island ... almost a continent by some reports ... quartered white oak and here we arrive at the mockups for our new project ... the octagons seemed simple until i actually had to add the kick spaces and the turned round pedestals ...

and here we arrive at the mockups for our new project ... the octagons seemed simple until i actually had to add the kick spaces and the turned round pedestals ... the base will be the first piece and it will have a 3/4" top that the cabinetry will be attached to from above ... like a really big puzzle ... more photos as we progress ....

the base will be the first piece and it will have a 3/4" top that the cabinetry will be attached to from above ... like a really big puzzle ... more photos as we progress ....

All in , all done .... miracle recovery .... descriptive post below

All in , all done .... miracle recovery .... descriptive post below We finished a couple of interesting repairs last week and I was sending photos to clients so I thought I would post them here too ... The bureau above is one of the last pieces of furniture we have to restore that was damaged in the fire I have occasionally written about. I thought it was a goner as it took several days in the sun to even get it open, and when we finally did, it really didnt look too promising ... Looks can be deceiving though and by the time Jim stripped the smoked shellac and sanded the interior and resealed it, I was starting to be just a little more optimistic. Click the photos to enlarge them ...

We finished a couple of interesting repairs last week and I was sending photos to clients so I thought I would post them here too ... The bureau above is one of the last pieces of furniture we have to restore that was damaged in the fire I have occasionally written about. I thought it was a goner as it took several days in the sun to even get it open, and when we finally did, it really didnt look too promising ... Looks can be deceiving though and by the time Jim stripped the smoked shellac and sanded the interior and resealed it, I was starting to be just a little more optimistic. Click the photos to enlarge them ... Here, Jim has stripped off the toasted shellac and sanded the interior, which he is now coating with a seal coat of shellac and wax to get rid of the smoke odor.

Here, Jim has stripped off the toasted shellac and sanded the interior, which he is now coating with a seal coat of shellac and wax to get rid of the smoke odor. There were then some repair necessary to the face that that you can see in the first photo above ...

There were then some repair necessary to the face that that you can see in the first photo above ... I chipped off what was left of the round corners and replaced them with new veneers. The masking tape was a good trick. It allowed me to bend the veneers cold without the pieces breaking or separating, kind of like a paper backed veneer would be, only thicker...

I chipped off what was left of the round corners and replaced them with new veneers. The masking tape was a good trick. It allowed me to bend the veneers cold without the pieces breaking or separating, kind of like a paper backed veneer would be, only thicker... I taped them in place with the repair mans friend, 3M 2040 masking tape, a stretchy but strong and sticky clamp..

I taped them in place with the repair mans friend, 3M 2040 masking tape, a stretchy but strong and sticky clamp.. The stripped and sanded drawers ... Whats up with that top one? ..

The stripped and sanded drawers ... Whats up with that top one? .. We applied a thin coat of aniline dye, recoating some elements a couple of times to balance the color, and then shellaced with a wash coat of diluted fresh amber shellac. Well build slowly in thin coats from here until we reach the desired shine, which will not be too terribly shiny ... The hardware has been cleaned and reantiqued and is ready to go back on when the finish is complete ... I think it will look like a million bucks when its done ...

We applied a thin coat of aniline dye, recoating some elements a couple of times to balance the color, and then shellaced with a wash coat of diluted fresh amber shellac. Well build slowly in thin coats from here until we reach the desired shine, which will not be too terribly shiny ... The hardware has been cleaned and reantiqued and is ready to go back on when the finish is complete ... I think it will look like a million bucks when its done ... Another fire victim in the before stage ....

Another fire victim in the before stage .... In the almost finished stage. The brass was polished and then reantiqued and the shellac was built slowly as mentioned above ... We finished the top with a coat of black patinating wax which was perfect for the job .... The Revere bowl was totally black and looked almost hopeless before Jim got to work on it ...

In the almost finished stage. The brass was polished and then reantiqued and the shellac was built slowly as mentioned above ... We finished the top with a coat of black patinating wax which was perfect for the job .... The Revere bowl was totally black and looked almost hopeless before Jim got to work on it ... This is another repair that came through recently from Hildene, Robert Todd Lincolns home, in Manchester, Vermont. We had a huge windstorm a couple of weeks ago, which blew open the French doors at the house and knocked the table across the room

This is another repair that came through recently from Hildene, Robert Todd Lincolns home, in Manchester, Vermont. We had a huge windstorm a couple of weeks ago, which blew open the French doors at the house and knocked the table across the room Before ...

Before ... After

After